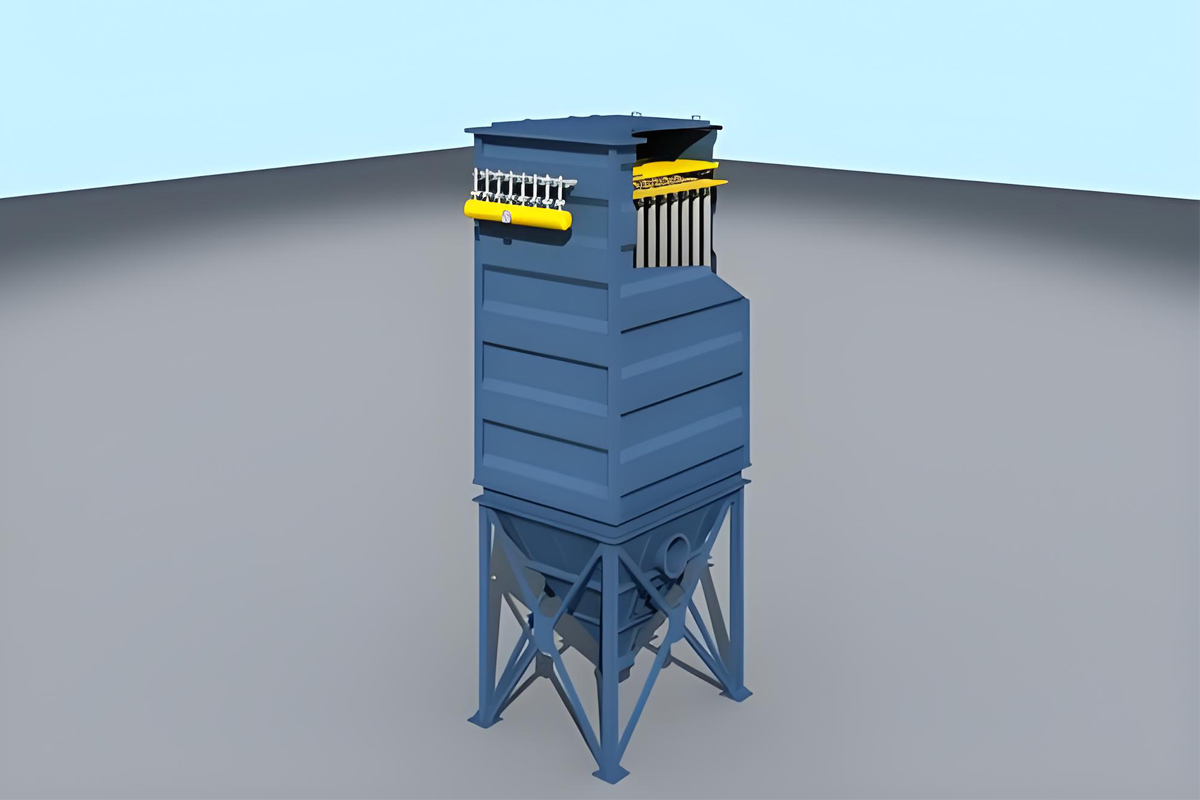

What is the Single pulse jet filter?

The single pulse jet filter is a small baghouse dust collector that employs high-pressure (0.5 to 0.7 MPa) large-flow pulse valves for sequential filter bag cleaning. This pulse jet filter has two cleaning methods: online pulse cleaning and offline pulse cleaning.

Working Principle of the Single pulse jet filter

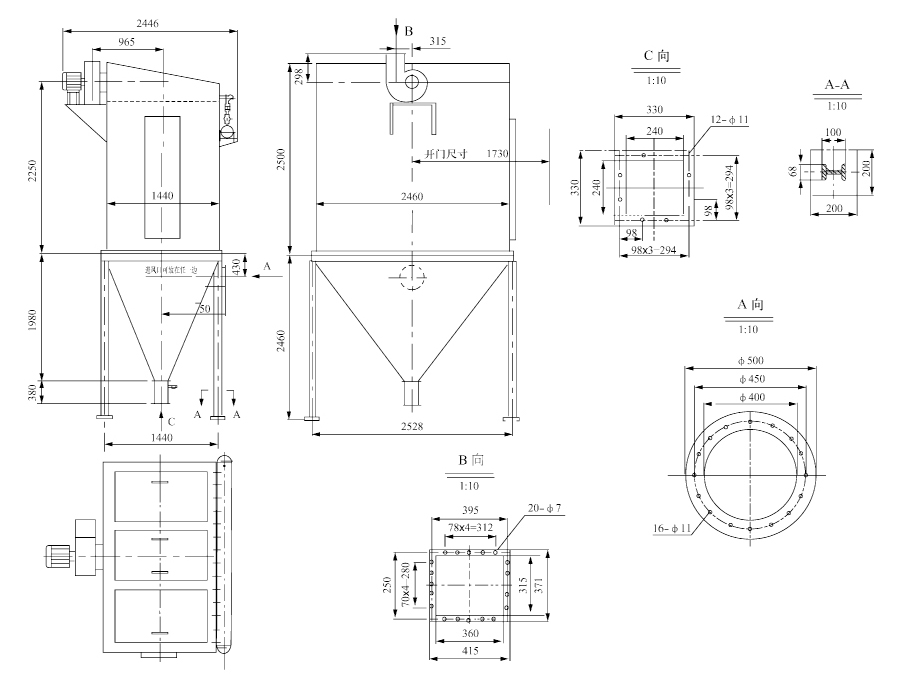

Dust-laden air enters the hopper or the filter bag chamber through the inlet. The contaminated air passes through the filter bags, where dust is filtered out, allowing clean air to enter the clean air chamber and exit through the outlet via a fan. Dust accumulates on the outer surface of the filter bags, increasing resistance. To ensure the equipment operates without exceeding 1200 Pa of resistance, regular dust cleaning is required.

Cleaning is controlled by a program controller that sequentially activates pulse valves, releasing compressed air (0.5 to 0.7 MPa) through the spray nozzle (referred to as primary air). This primary air induces several times its volume of surrounding air (referred to as secondary air) into the filter bag, expanding rapidly in an instant. The reverse airflow dislodges the dust, achieving the cleaning purpose.

Performance Model | HMC-32 | HMC-48 | HMC-64 | HMC-80 | HMC-96 | HMC-112 | |

Processing air volume(m3/h) | 1500-2100 | 2100-3200 | 2900-4300 | 4000-6000 | 5200-7000 | 6000-9000 | |

Total filter area(m2) | 24 | 36 | 48 | 60 | 72 | 84 | |

Filter wind speed(m/min) | 1.00-1.50 | 1.00-1.50 | 1.00-1.50 | 1.10-1.70 | 1.20-1.70 | 1.20-1.80 | |

Number of filter bags (bars) | 32 | 48 | 64 | 80 | 96 | 112 | |

Inlet gas temperature (℃) | ≤120℃ | ||||||

Dust collector resistance (Pa) | ≤1200 | ||||||

Import dust concentration (g/m3) | <200 | ||||||

Import emission concentration (mg/m3) | ≤100 | ||||||

Compressed air for cleaning | Pressure(Pa) | 5~7×10⁵ | |||||

Air consumption (m3/min) | 0.10 | 0.14 | 0.20 | 0.24 | 0.29 | 0.34 | |

Withstand negative pressure (Pa) | 5000 | ||||||

Pulse valve quantity (pieces) | 4 | 6 | 8 | 10 | 12 | 14 | |

Fan motor power (KW) | 1.5 | 3.0 | 3.0 | 5.5 | 5.5 | 7.5 | |

Weight(kg) | Type A (with ash hopper) | 1350 | 1620 | 1850 | 2360 | 2800 | 3200 |

Type B (without ash hopper) | 1220 | 1470 | 1670 | 2150 | 2540 | 2880 | |

Advantages of the Single Pulse Jet Filter

The single pulse jet filter has strong dust cleaning capability, low emissions concentration, low leakage rate, low energy consumption, low steel consumption, small footprint, stable operation, and good economic benefits. It is suitable for the purification of dust-laden gases and material recovery in industries such as metallurgy, building materials, cement, machinery, chemicals, power, and light industry.

The single pulse jet filter can achieve the purpose of dust cleaning with one blowing, thus extending the cleaning cycle and reducing cleaning energy consumption. The consumption of compressed air can be greatly reduced. Meanwhile, the fatigue level of the filter bag and pulse valve is also correspondingly reduced, thereby greatly extending the lifespan of the filter bag and valve components.

The filter bag’s opening uses an elastic expansion ring, which has good sealing performance and is firm. The filter bag support frame adopts a multi-angular shape, which reduces the friction between the bag and the frame, extends the bag’s lifespan, and facilitates bag removal.

The top bag extraction method is adopted; when changing bags, the skeleton is pulled out, and the dirty bag is placed into the lower ash hopper of the housing, where it can be removed through the manhole, thus improving the bag changing operation conditions.

The single pulse jet filter features a gas-tight design with good sealing performance. The inspection doors use high-quality sealing materials, and during the manufacturing process, kerosene is used for leak detection, resulting in a very low leakage rate.

The layout of the inlet and outlet ducts is compact, resulting in low air resistance.

Application of the Single pulse jet filter

The single pulse jet filter, designed specifically for handling small air volumes and moderate temperatures, is an excellent piece of equipment that demonstrates outstanding performance and wide application value across various industrial fields. Whether it’s controlling dust during coal mining, purifying flue gas in steel smelting, recovering fly ash in the power industry, or capturing fine particles in chemical production, the single-unit pulse bag dust collector can serve as an indispensable environmental protector in these areas, thanks to its efficient and stable dust removal capabilities.

In processes such as sintering, iron smelting, and steel making, the single pulse jet filter can effectively remove dust and waste gas, reducing environmental pollution and increasing production rates.

During cement production, processes like raw material grinding and clinker firing generate a large amount of dust. The single pulse jet filter can efficiently collect and handle this dust, reducing environmental pollution and improving product quality.

We are a team of technically knowledgeable, competent as well as well-trained personnel who altogether serve to our existing customers at their best. We are always ready to fetch the after sale assistance whenever and wherever required by our clients.

In processes such as ore crushing and screening, the single pulse jet filter can collect and process dust, reducing environmental pollution and enhancing resource utilization.

In the manufacturing processes of products like ceramics and glass, the single pulse jet filter can handle the generated dust, ensuring a clean production environment and protecting employee health.

In processes such as sawing and sanding, the single pulse jet filter can effectively remove sawdust and dust, ensuring production safety.

During grinding and screening, the single pulse jet filter can remove dust, ensuring production safety and improving product quality.

In processes like spinning and weaving, the single pulse jet filter can remove fiber dust, enhancing the quality of textiles.

In coal-fired power plants, the single pulse jet filter can effectively remove smoke dust and pollutants such as sulfur dioxide, reducing environmental pollution and increasing power generation rates

In operations such as metal cutting and casting, the single pulse jet filter can collect and process metal dust, protecting the respiratory health of employees.

Customization Service Process

Provide customization services according to different working conditions

download brochure

Please download our document to see specific data of the aservice and how we work.

Let’s Start Work Together

No.218, Xisu Road, Huji Street

HaianHigh-tech Zone (formerly Haian Town)

sales@darko-tech.com

9.00AM – 18.00PM