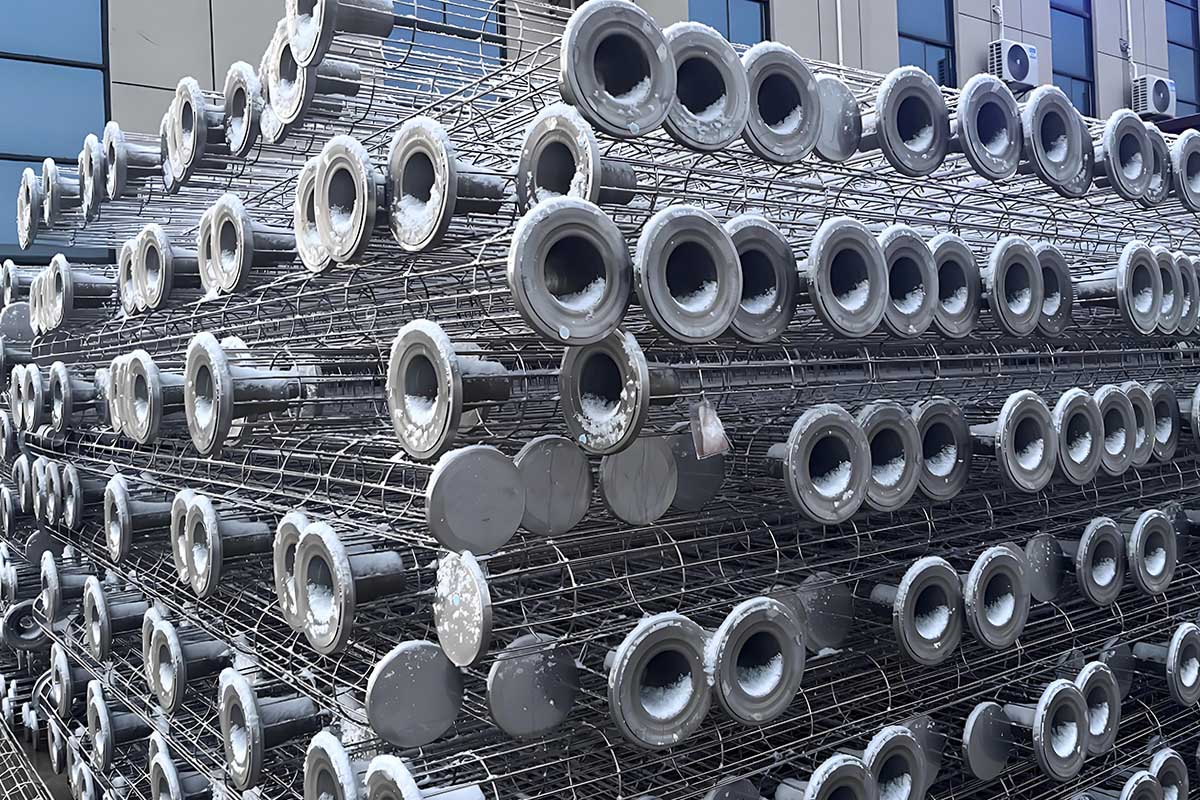

Stainless Steel Bag Cage Product Details

Product Overview

Stainless steel bag cages are essential components in filtration systems designed to handle corrosive substances and high-temperature environments. Typically made from 304 or 316 stainless steel, these cages provide durability and reliability in various applications.

Advantages of Stainless Steel Bag Cages

Stainless steel bag cages are widely used in filtration equipment across diverse industries. They offer several distinct advantages over traditional bag filters.

1. Material Advantages

Stainless steel is renowned for its excellent corrosion resistance, which significantly extends the service life of bag cages. In corrosive environments involving acids, bases, and salts, stainless steel bag cages maintain optimal performance without easily corroding or sustaining damage. Additionally, stainless steel exhibits good wear and impact resistance, ensuring stable operation in complex working conditions.

2. Filtration Performance Advantages

Stainless steel bag cages deliver superior filtration performance. They effectively remove particles, suspended solids, microorganisms, and other impurities from liquids or gases, enhancing material cleanliness. Their unique filtration design ensures efficient and uniform filtering, resulting in consistent and stable filtration outcomes. Customization options are available to meet specific specifications and filtration accuracy requirements.

3. Installation and Maintenance Advantages

Stainless steel bag cages are easy to install and maintain, which significantly reduces operational costs. Their modular design allows users to quickly assemble and disassemble the cages based on actual needs, facilitating transportation and handling. Replacing filter bags is straightforward; users simply remove the old bag and install a new one, making the process quick and efficient.

4. Safety Performance Advantages

Stainless steel bag cages offer excellent safety features, ensuring the health and safety of operators. The non-toxic and odorless material poses no environmental pollution risk. Additionally, these cages are equipped with safety features, such as pressure relief valves, to prevent accidents caused by excessive pressure or bag rupture.

5. Environmental Performance Advantages

Stainless steel bag cages positively impact environmental protection by effectively reducing pollution. Made from reusable materials, they minimize waste generation. Furthermore, their easy-to-clean design allows for reuse, further lowering their environmental footprint.

6. Economic Performance Advantages

The economic performance of stainless steel bag cages is another critical factor in their widespread use. Although stainless steel may have a higher initial cost, its longevity and low maintenance reduce overall expenses. Moreover, these cages enhance production efficiency and work quality, leading to greater economic benefits for enterprises.

Application Fields

Manufacturing Specifications

When manufacturing stainless steel bag cages, specific production requirements must be observed. The cage framework should primarily use 304 stainless steel, with sufficient vertical supports included. The maximum distance between two vertical supports should not exceed 20 mm. The spacing between horizontal support rings depends on the cage diameter. These requirements ensure the quality and performance of the stainless steel bag cages.

Summary

Stainless steel bag cages are vital filtration and support devices used across various fields. Their characteristics—such as corrosion resistance, high-temperature resistance, high strength, and good rigidity—make them an ideal choice for efficient filtration solutions. Understanding their benefits allows for better selection and utilization, ultimately improving production efficiency and work quality.For more information, please visit Darko.

download brochure

Please download our document to see specific data of the aservice and how we work.

Let’s Start Work Together

No.218, Xisu Road, Huji Street

HaianHigh-tech Zone (formerly Haian Town)

sales@darko-tech.com

9.00AM – 18.00PM