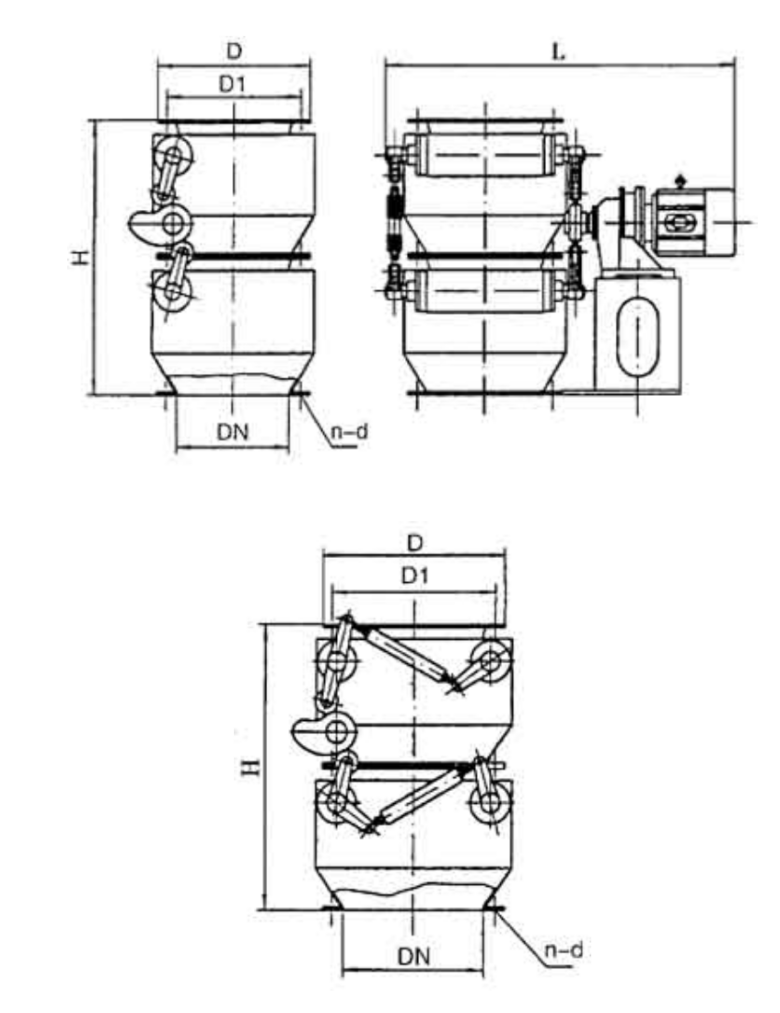

Double Dump Valve

The Double Dump Valve is designed to handle chunky or fibrous materials that can jam ordinary rotary valves. Its durable construction allows it to move abrasive materials effortlessly. The Darko valve features tandem gates that maintain proper pressure above and below the valve. It also includes a reinforced closure mechanism to prevent air seepage. This double flap valve can operate on air or electricity and requires minimal maintenance.

Key Features

Advantages

Double dump valves minimize wear and tear. Unlike rotary valves, they do not experience air leakage over time. They allow seamless material flow while preventing backflow of air or gas. This is crucial for maintaining system safety and stability.

Typical Applications

You can use double dump valves in various situations, including:

Materials Handled

These valves effectively manage a range of materials, such as:

As long as the material is granular, non-sticky, and flows freely by gravity, it can be processed by a double dump valve.

Specifications

There are different sizes of double dump valves offered (listed below).

Applicable media | Operating temperature | Ash discharge capacity |

dry powder | 150℃ | 1.5-300m3/h |

DN | D1 | D | H | H1 | L | n-d | Ash discharge capacity m3/h | Transmission model | Opening and closing frequency/min | power kw |

150 | 196 | 226 | 460 |

| 1400 | 6-Φ11 | 1.5~2 | BWY-15-59 | 25 | 0.6 |

200 | 245 | 280 | 580 |

| 1500 | 8-Φ11 | 4~5 | BWY-15-59 | 25 | 0.6 |

220 | 265 | 300 | 580 |

| 1540 | 8-Φ11 | 5~7 | BWY-15-59 | 25 | 0.6 |

250 | 300 | 340 | 580 |

| 1610 | 12-Φ11 | 5~8 | BWY-15-59 | 21 | 0.8 |

300 | 350 | 390 | 620 |

| 1840 | 12-Φ13 | 7~12 | BWY-15-59 | 21 | 1.1 |

320 | 370 | 410 | 700 |

| 1980 | 12-Φ13 | 9~15 | BWY-15-59 | 21 | 1.1 |

400 | 450 | 490 | 800 | 660 | 2060 | 12-Φ13 | 12~15 | BWY-15-59 | 12 | 1.66 |

450 | 500 | 540 | 800 | 740 | 2180 | 12-Φ13 | 16~34 | BWY-15-59 | 12 | 1.66 |

500 | 560 | 600 | 950 | 800 | 2210 | 12-Φ13 | 20~45 | BWY-15-59 | 12 | 1.66 |

600 | 660 | 700 |

| 920 | 2310 | 16-Φ13 | 34~72 | BWY-15-59 | 12 | 3.18 |

720 | 780 | 820 |

| 1060 | 2380 | 16-Φ13 | 51~110 | BWY-15-59 | 12 | 3.18 |

800 | 870 | 920 |

| 1150 | 2420 | 16-Φ13 | 77~160 | BWY-15-59 | 12 | 3.18 |

1000 | 1080 | 1140 |

| 1450 | 2640 | 20-Φ18 | 150~300 | BWY-15-59 | 8 | 4.3 |

Conclusion: Enhance Your Material Handling

Double dump valves perform reliably under harsh conditions. They ensure smooth material flow in manufacturing processes. These valves offer a low-maintenance alternative to rotary valves. They are perfect for applications requiring movement between different pressure environments.

Whether you are processing fly ash, chemical powders, or construction materials, double dump valves provide efficient and safe material handling. They contribute significantly to the infrastructure of our society.

download brochure

Please download our document to see specific data of the aservice and how we work.

Let’s Start Work Together

No.218, Xisu Road, Huji Street

HaianHigh-tech Zone (formerly Haian Town)

sales@darko-tech.com

9.00AM – 18.00PM