Slide Gate Valve

The Slide Gate Valve is designed for various gravity feed applications, including silos, hoppers, and screw conveyors. It effectively isolates materials, ensuring smooth operation in industrial settings.

Design and Functionality

A slide gate valve is essential for controlling fluid flow in pipelines. Its main components include:

When you turn the handwheel, the valve stem pushes the gate back and forth through a threaded mechanism. This motion controls the flow of materials, allowing for precise opening and closing.

Materials and Sealing

The sealing materials used in slide gate valves typically consist of hard alloys or polytetrafluoroethylene (PTFE). These materials resist high temperatures and corrosion, ensuring the valve’s stability and sealing performance over time.

Key Features

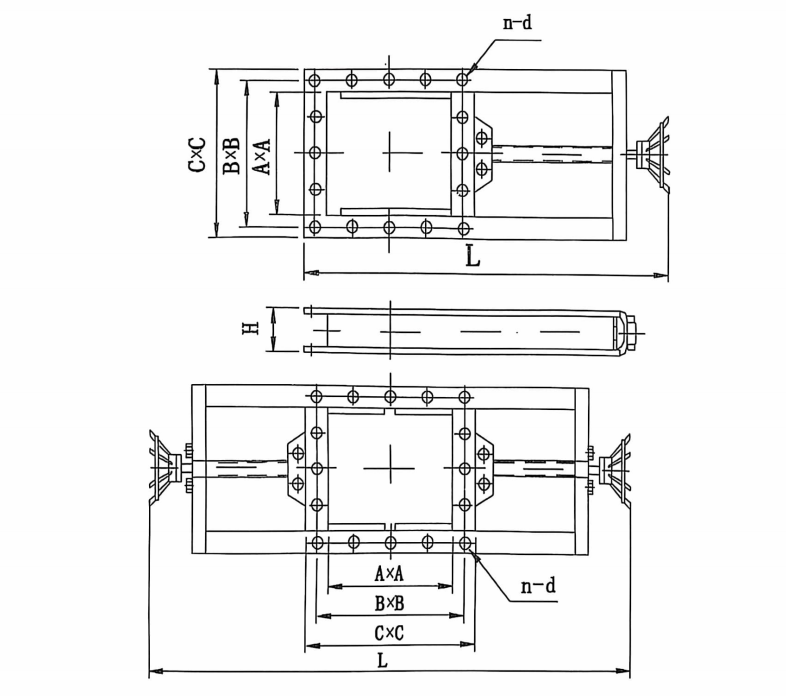

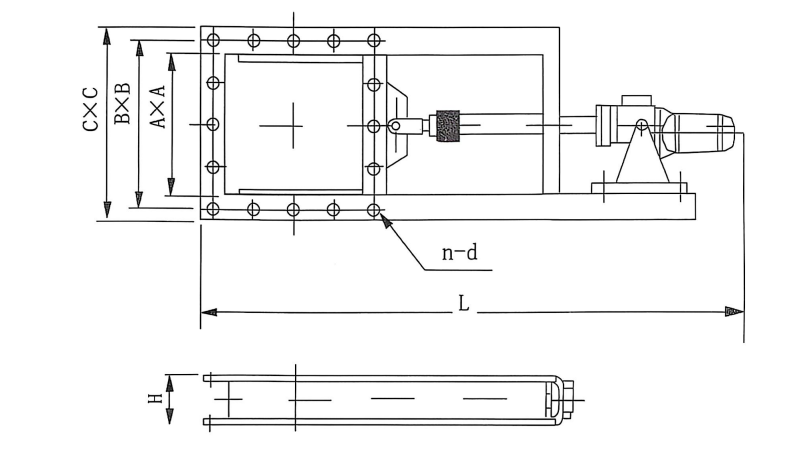

Manual slide gate valve

Type | A×A | B×B | C×C | L | H | n-d | Weight (Kg) |

One way | 200×200 | 256×256 | 306×306 | 820 | 120 | 8-φ14 | 62 |

250×250 | 306×306 | 346×346 | 930 | 120 | 8-φ14 | 70.5 | |

300×300 | 356×356 | 396×396 | 1050 | 120 | 8-φ14 | 81 | |

400×400 | 456×456 | 496×496 | 1400 | 140 | 12-φ14 | 114 | |

450×450 | 510×510 | 556×556 | 1450 | 140 | 12-φ18 | 130 | |

500×500 | 560×560 | 606×606 | 1610 | 140 | 16-φ18 | 147 | |

Two way

| 600×600 | 660×660 | 706×706 | 1830 | 160 | 16-φ18 | 169 |

700×700 | 770×770 | 820×820 | 2130 | 160 | 20-φ18 | 236 | |

800×800 | 870×870 | 920×920 | 2440 | 180 | 20-φ18 | 303 | |

900×900 | 974×974 | 1030×1030 | 2660 | 180 | 24-φ23 | 424 | |

1000×1000 | 1074×1074 | 1130×1130 | 2870 | 180 | 24-φ23 | 636 |

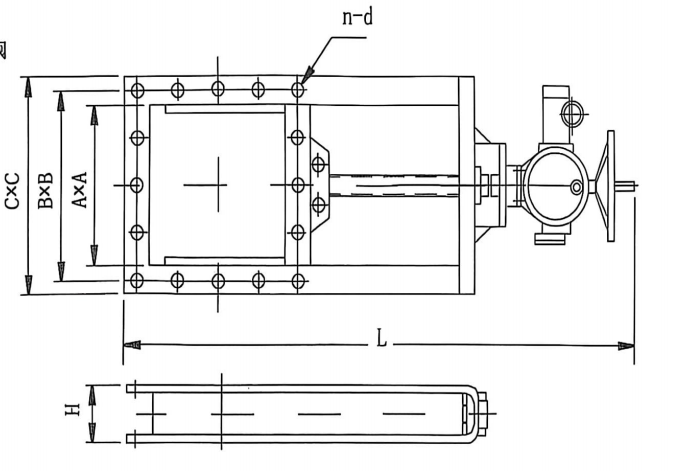

Electrical slide gate valve

Type | A×A | B×B | C×C | L | H | n-d | Weight (Kg) |

One way | 200×200 | 256×256 | 306×306 | 920 | 120 | 8-φ14 | 130 |

| 250×250 | 306×306 | 346×346 | 1050 | 120 | 8-φ14 | 150 |

| 300×300 | 356×356 | 396×396 | 1260 | 120 | 8-φ14 | 180 |

| 400×400 | 456×456 | 496×496 | 1560 | 140 | 12-φ14 | 200 |

| 450×450 | 510×510 | 556×556 | 1670 | 140 | 12-φ18 | 230 |

| 500×500 | 560×560 | 606×606 | 1890 | 140 | 16-φ18 | 270 |

Two way

| 600×600 | 660×660 | 706×706 | 1830 | 160 | 16-φ18 | 350 |

| 700×700 | 770×770 | 820×820 | 2520 | 160 | 20-φ18 | 390 |

| 800×800 | 870×870 | 920×920 | 2750 | 180 | 20-φ18 | 460 |

| 900×900 | 974×974 | 1030×1030 | 2950 | 180 | 24-φ23 | 490 |

| 1000×1000 | 1074×1074 | 1130×1130 | 3110 | 180 | 24-φ23 | 555 |

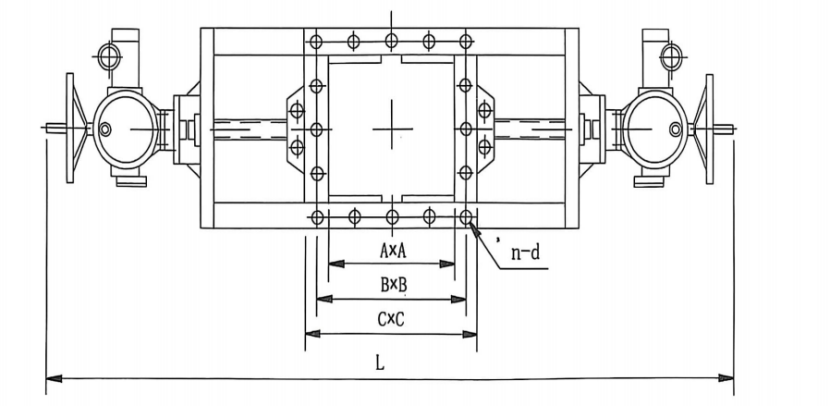

Electric draw stem slide gate valve

A×A | B×B | C×C | L | H | n-d | Weight (Kg) |

200×200 | 256×256 | 306×306 | 920 | 120 | 8-φ14 | 130 |

250×250 | 306×306 | 346×346 | 1050 | 120 | 8-φ14 | 150 |

300×300 | 356×356 | 396×396 | 1260 | 120 | 8-φ14 | 180 |

400×400 | 456×456 | 496×496 | 1560 | 140 | 12-φ14 | 200 |

450×450 | 510×510 | 556×556 | 1670 | 140 | 12-φ18 | 230 |

500×500 | 560×560 | 606×606 | 1890 | 140 | 16-φ18 | 270 |

600×600 | 660×660 | 706×706 | 1830 | 160 | 16-φ18 | 320 |

700×700 | 770×770 | 820×820 | 2520 | 160 | 20-φ18 | 350 |

800×800 | 870×870 | 920×920 | 2750 | 180 | 20-φ18 | 410 |

900×900 | 974×974 | 1030×1030 | 2950 | 180 | 24-φ23 | 450 |

1000×1000 | 1074×1074 | 1130×1130 | 3110 | 180 | 24-φ23 | 505 |

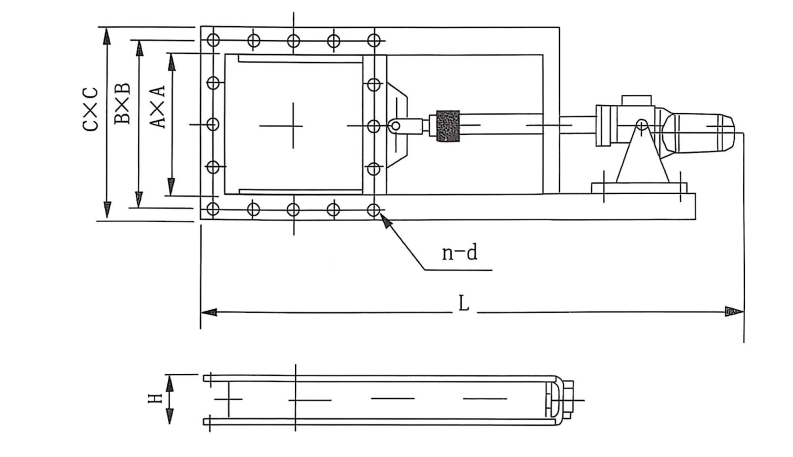

Electric hydraulic draw stem slide gate valve

A×A | B×B | C×C | L | H | n-d | Weight (Kg) |

200×200 | 256×256 | 306×306 | 920 | 120 | 8-φ14 | 130 |

250×250 | 306×306 | 346×346 | 1050 | 120 | 8-φ14 | 150 |

300×300 | 356×356 | 396×396 | 1260 | 120 | 8-φ14 | 180 |

400×400 | 456×456 | 496×496 | 1560 | 140 | 12-φ14 | 200 |

450×450 | 510×510 | 556×556 | 1670 | 140 | 12-φ18 | 230 |

500×500 | 560×560 | 606×606 | 1890 | 140 | 16-φ18 | 270 |

600×600 | 660×660 | 706×706 | 1830 | 160 | 16-φ18 | 320 |

700×700 | 770×770 | 820×820 | 2520 | 160 | 20-φ18 | 350 |

800×800 | 870×870 | 920×920 | 2750 | 180 | 20-φ18 | 410 |

900×900 | 974×974 | 1030×1030 | 2950 | 180 | 24-φ23 | 450 |

1000×1000 | 1074×1074 | 1130×1130 | 3110 | 180 | 24-φ23 | 505 |

Applications

Slide gate valves are widely utilized across various industries, including:

Their simple structure, low manufacturing cost, and long service life make them ideal for handling coarse fluid media. They perform well under harsh conditions, including both low and high temperatures.

Operational Versatility

Slide gate valves can be operated manually or through electric motor drives, adapting to different operational requirements. This flexibility enhances their usability in diverse applications.

Conclusion

The slide gate valve is a reliable solution for controlling flow in gravity feed applications. Its robust design, material resilience, and versatility make it an excellent choice for various industrial environments. Whether you’re managing coal, chemicals, or water treatment, the slide gate valve provides dependable performance and longevity.

download brochure

Please download our document to see specific data of the aservice and how we work.

Let’s Start Work Together

Graaf Florisstraat 22A,3021 CH

Gracontruction@gmail.com

10.00AM – 18.00PM