The Ultimate Guide to Bucket Elevators: Types, Uses & Maintenance Tips

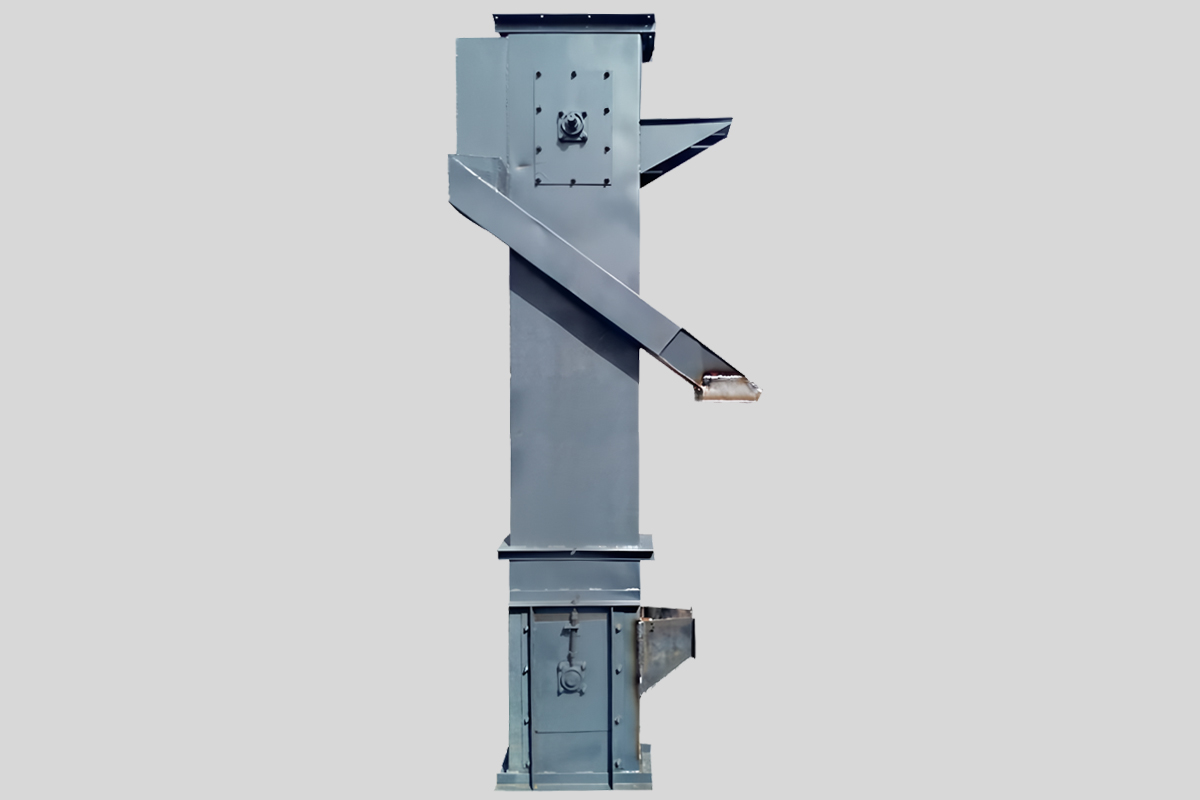

What is a Bucket Elevator?

A bucket elevator is an essential industrial material handling system designed for vertical transportation of bulk materials. These robust machines efficiently move everything from grains and fertilizers to mineral powders and chemical compounds using a series of buckets mounted on chains or belts. As one of the most versatile bulk material handling solutions, bucket elevators serve critical functions across multiple industries including:

- Agriculture and grain processing

- Food manufacturing

- Chemical production

- Construction materials

- Mining and mineral processing

This comprehensive guide covers all aspects of bucket elevator operation, from understanding different types and their applications to proper maintenance practices that extend equipment lifespan.

What Is the Use of a Bucket Conveyor?

Bucket elevators provide unmatched efficiency in vertical material transport with several key advantages over alternative systems:

Primary Industrial Uses:

1.Grain Handling Systems

- Perfect for wheat, corn, soybeans and other agricultural products

- Gentle handling preserves grain quality

- Dust-tight designs maintain food safety standards

2.Chemical Processing

- Safely transports fertilizers, plastic pellets and industrial salts

- Corrosion-resistant models available

- Explosion-proof options for hazardous materials

3.Construction Materials

- Heavy-duty models handle cement, sand and limestone

- High-capacity designs for bulk material transfer

- Durable construction withstands abrasive materials

4.Mining Operations

- Specialized versions for coal, ores and slag

- Extreme-duty components for harsh environments

- Custom configurations for unique material properties

Key Features

Bucket elevators offer vertical material transportation with these advantages:

Low power consumption: Uses gravity feeding and induced discharge to minimize energy waste.

Wide material compatibility: Handles powders, small particles, and abrasive materials while maintaining good sealing.

High reliability: Advanced design ensures over 20,000 hours of trouble-free operation with smooth performance at great heights.

Long service life: Gravity feeding reduces material collision and wear.

Classifications of Bucket Elevators

Based on structure and operation, bucket elevators are categorized as:

1.By driving mechanism:

- Belt-type: Uses rubber/nylon belts for light, non-abrasive materials (grains, feed).

- Chain-type: Uses metal chains for heavy, high-temperature, or abrasive materials (ores, coal).

2.By discharge method:

- Centrifugal discharge: High speed (1.5-3.5 m/s) for free-flowing materials (grains).

- Gravity discharge: Low speed (0.4-1.2 m/s) for fragile/sticky materials (wet sand, fertilizer).

- Combined discharge: Uses both methods for versatile applications.

3.By structure:

- Vertical: Standard design for most applications.

- Inclined: Used when angled lifting is required (more complex structure).

Chain vs. Belt Bucket Elevators

| Feature | Chain-Type | Belt-Type |

|---|---|---|

| Driving part | Metal chains (durable, heat-resistant) | Rubber/nylon belts (lightweight, quiet) |

| Suitable materials | Heavy, abrasive, high-temp materials (ores, coal) | Light, non-abrasive materials (grains, plastics) |

| Maintenance | Higher (chain lubrication needed) | Lower (easy belt replacement) |

| Speed | Lower (0.4-1.2 m/s) | Higher (1.5-3.5 m/s) |

| Lifespan | Longer (wear-resistant) | Shorter (prone to aging/tearing) |

Operating Speed of Bucket Elevators

Speed depends on material properties and discharge method:

- Centrifugal discharge: 1.5-3.5 m/s (high speed for free-flowing materials).

- Gravity discharge: 0.4-1.2 m/s (low speed for fragile/sticky materials).

- Proper speed ensures efficient operation without material spillage.

Maintenance Tips

For long-term stable operation:

Inspect chains/belts regularly for wear and tension.

Lubricate chains periodically (chain-type only).

Clean residual materials to prevent clogging.

Check bearings and drive units for smooth operation.

Tighten bolts to prevent loosening from vibrations.

Conclusion

Bucket elevators are vital for vertical material transport in industries like food processing, chemicals, and mining. Selecting the right type (chain/belt), optimizing speed, and performing regular maintenance will maximize efficiency and lifespan.

For expert advice on selection or maintenance, contact our team. We’ll recommend the best model based on your material properties, capacity, and working conditions, plus provide a maintenance plan for optimal performance.