Plenum Pulse Jet Baghouse (PPCS)

Product Overview

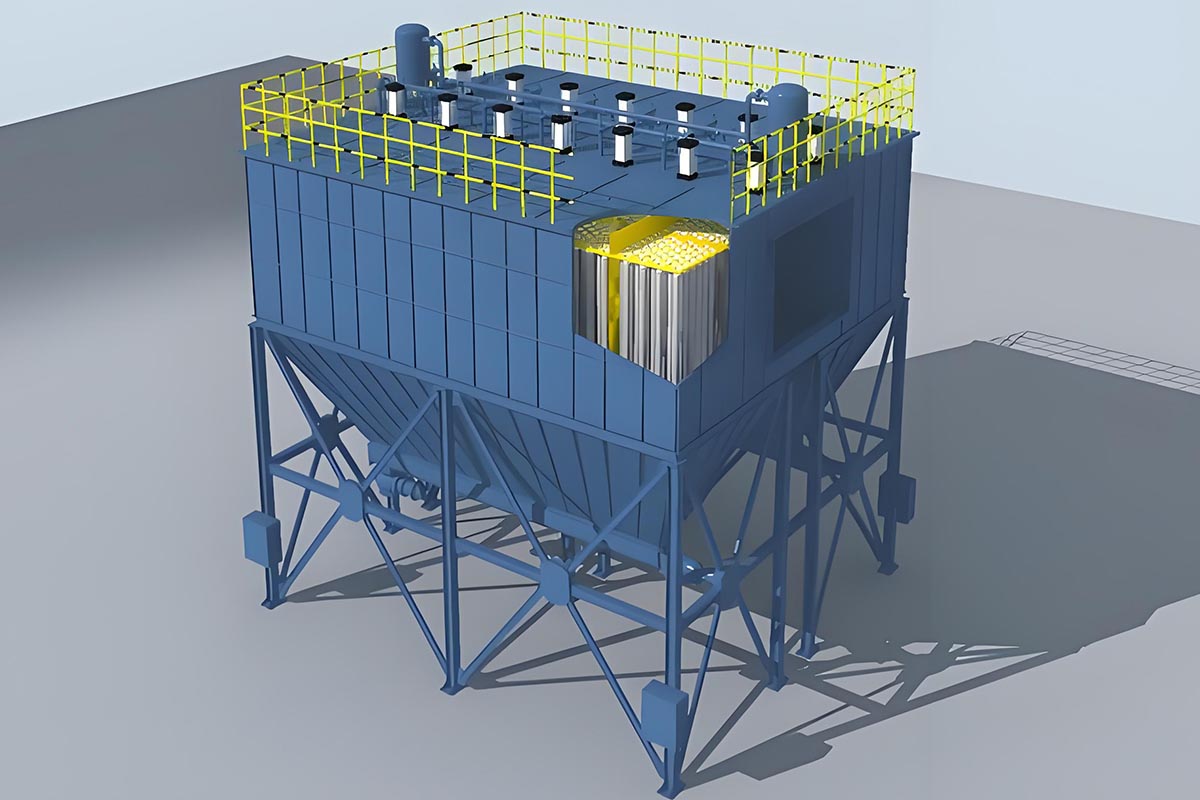

The Plenum Pulse Jet Baghouse is an efficient bag filter that utilizes air pulse technology for dust removal. It is particularly suitable for directly handling dust-laden, flammable, and explosive gases.This equipment leverages air pulses from a pre-pressurized chamber, offering several advantages:

Technical Advantages

- Efficient Cleaning: By combining the benefits of chamber back-blowing and pulse jet cleaning, it overcomes the limitations of traditional methods.

- Increased Efficiency: The design expands the application range of bag dust collectors, enhances operational efficiency, and prolongs filter bag lifespan.

Innovative Design Features

Specifications

Type | PPCS 32~64 | ||||||||

32-3 | 32-4 | 32-5 | 32-6 | 64-4 | 64-5 | 64-6 | 64-7 | 64-8 | |

Air volume( m3/h) | 6900 | 8930 | 11160 | 13390 | 17800 | 22300 | 26700 | 31200 | 35700 |

Air to cloth ration(m/min) | 1.2~2.0 | ||||||||

filtration area (m2) | 93 | 124 | 155 | 186 | 248 | 310 | 372 | 434 | 496 |

chambers (pcs) | 3 | 4 | 5 | 6 | 4 | 5 | 6 | 7 | 8 |

filter bags (pcs) | 96 | 128 | 160 | 192 | 256 | 320 | 384 | 448 | 512 |

resistance (Pa) | 1470~1770 | ||||||||

Inlet dust concentration g/m3 | <200 | ||||||||

Outlet dust concentration g/m3 | <0.1 | ||||||||

negative pressure (Pa) | 5000 | ||||||||

Air consumption (m3/min) | 0.278 | 0.37 | 0.46 | 0.55 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 |

Pulse valve Size (inches) | 21/2“ | ||||||||

Pulse valve Quantity (pcs) | 3 | 4 | 5 | 6 | 4 | 5 | 6 | 7 | 8 |

Cylinder | ∅63~100 | ||||||||

Type | PPCS 96 | |||||||||||

96-4 | 96-5 | 96-6 | 96-7 | 96-8 | 96-9 | 96- 2×5 | 96- 2×6 | 96- 2×7 | 96- 2×8 | 96- 2×9 | 96- 2×10 | |

Air volume( m3/h) | 26800 | 33400 | 40100 | 46800 | 53510 | 60100 | 67250 | 80700 | 94100 | 107600 | 121000 | 134500 |

Air to cloth ration(m/min) | 1.2~2.0 | |||||||||||

filtration area (m2) | 372 | 465 | 557 | 650 | 774 | 836 | 934 | 1121 | 1308 | 1494 | 1681 | 1868 |

chambers (pcs) | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 14 | 16 | 18 | 20 |

filter bags (pcs) | 384 | 480 | 576 | 672 | 768 | 864 | 960 | 1152 | 1344 | 1536 | 1728 | 1920 |

resistance (Pa) | 1470~1770 | |||||||||||

Inlet dust concentration g/m3 | <1300 | |||||||||||

Outlet dust concentration g/m3 | <0.1 | |||||||||||

negative pressure (Pa) | 5000 | |||||||||||

Air consumption (m3/min) | 1.2 | 1.5 | 1.5 | 2.1 | 2.4 | 2.7 | 2.7 | 3.4 | 4.2 | 4.8 | 5.4 | 6.0 |

Pulse valve Size (inches) | 21/2“ | |||||||||||

Pulse valve Quantity (pcs) | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 14 | 16 | 18 | 20 |

Cylinder | ∅100 | |||||||||||

Type | PPCS 128 | ||||||||||

128-6 | 128-9 | 128-10 | 128- 2×6 | 128-2×7 | 128- 2×8 | 128- 2×9 | 128- 2×10 | 128- 2×11 | 128- 2×12 | 128- 2×13 | |

Air volume( m3/h) | 67300 | 100900 | 112100 | 134600 | 157000 | 179400 | 201900 | 224300 | 247600 | 269100 | 291600 |

Air to cloth ration(m/min) | 1.2~2.0 | ||||||||||

filtration area (m2) | 935 | 1402 | 1558 | 1869 | 2181 | 2492 | 2804 | 3115 | 3427 | 3738 | 4050 |

chambers (pcs) | 6 | 9 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 |

filter bags (pcs) | 768 | 1152 | 1280 | 1536 | 1792 | 2084 | 2304 | 2560 | 2816 | 3072 | 3328 |

resistance (Pa) | 1470~1770 | ||||||||||

Inlet dust concentration g/m3 | <1300 | ||||||||||

Outlet dust concentration g/m3 | <0.1 | ||||||||||

negative pressure (Pa) | 6860 | ||||||||||

Air consumption (m3/min) | 3.6 | 5.4 | 6.0 | 7.0 | 8.3 | 9.5 | 10.7 | 12 | 13.1 | 14.3 | 15.5 |

Pulse valve Size (inches) | 21/2“ | ||||||||||

Pulse valve Quantity (pcs) | 6 | 9 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 |

Cylinder | ∅100 | ||||||||||

Application Areas

The Plenum Pulse Jet Baghouse finds extensive use in various dust collection systems in cement plants, including:

It is also suitable for collecting dust from coal mills, with potential structural modifications based on requirements, effectively handling gas concentrations exceeding 1000 g/m³. Additionally, it serves in metallurgy, chemical processing, machinery industries, and municipal boilers.

Materials and Design

This series of filter bags typically comprises polyester needle-punched felt, allowing a maximum operating temperature below 120°C. If utilizing aramid needle-punched felt, the permissible temperature can reach 210°C. In cases where exhaust gas temperatures exceed the allowable limits for filter materials, cooling measures must be implemented before the gas enters the dust collector.

This series of Plenum Pulse Jet Baghouses is designed for outdoor use, offering various specifications. Each chamber accommodates 32, 64, 96, or 128 filter bags, providing 33 different specifications to choose from. The filter bag diameter is 130 mm, with lengths of 2450 mm and 3060 mm. The baghouse operates under either negative or positive pressure, achieving dust removal efficiencies exceeding 99%, with purified gas concentrations below 100 mg/m³.

In cold regions, if the outdoor heating design temperature is ≤ -25°C, additional heating devices must be included, potentially requiring appropriate modifications to the baghouse.

Customization Service Process

Provide customization services according to different working conditions.For more information, please visit Darko.

download brochure

Please download our document to see specific data of the aservice and how we work.

Let’s Start Work Together

No.218, Xisu Road, Huji Street

HaianHigh-tech Zone (formerly Haian Town)

sales@darko-tech.com

9.00AM – 18.00PM