Rotary Valve

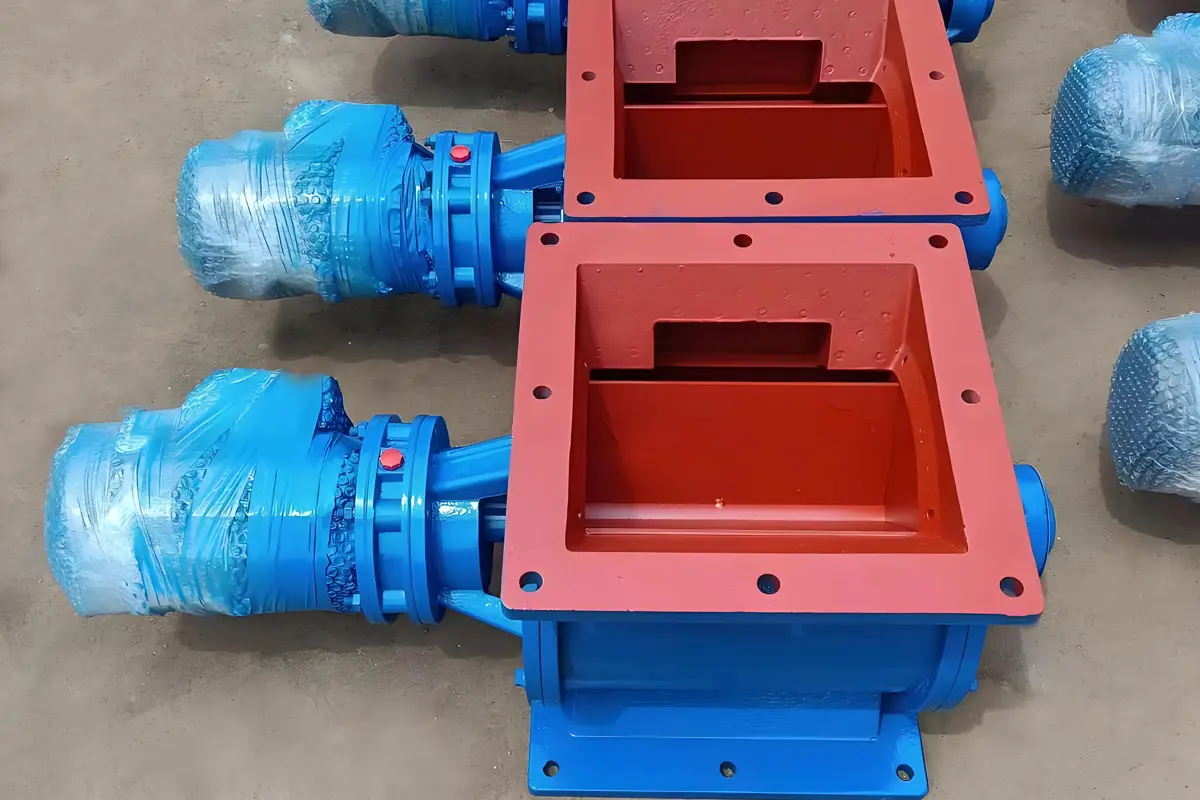

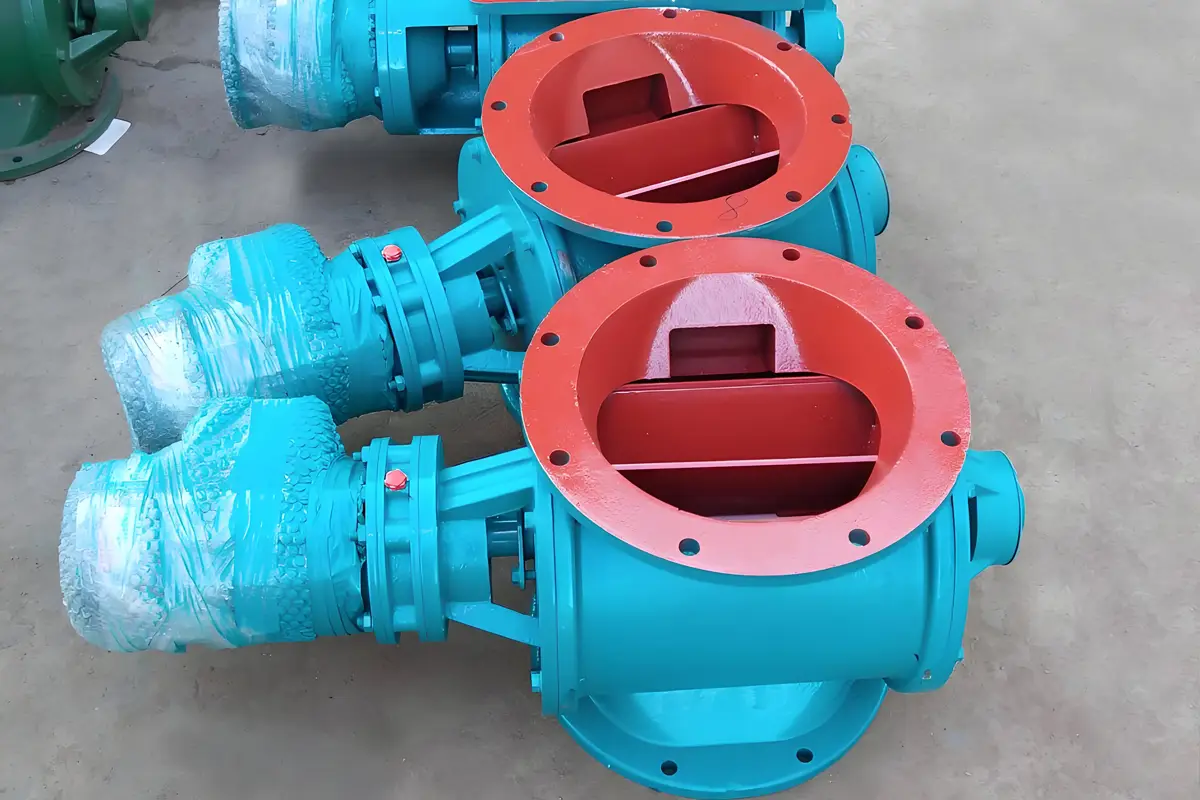

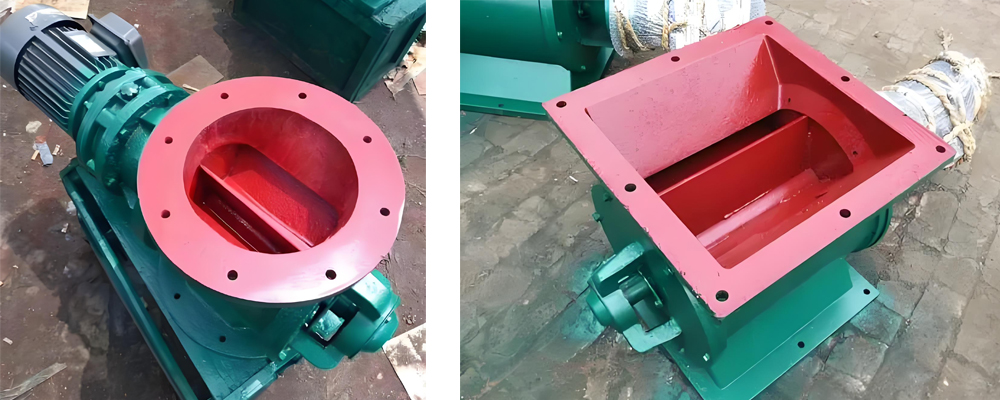

The prime function of a rotary airlock valve is to regulate the flow from one chamber to another while maintaining a good airlock condition. The product is mainly in dry powder or granular form.

In the dust filtration field a good airlock is essential on cyclone and bag filter applications in order that the manufacturers quoted high dust collection efficiencies can be maintained. Airlocks are also important in the pneumatic conveying industry, where product is regulated into a pressure or vacuum conveying line while minimising air leakage.For more information, please visit Darko.

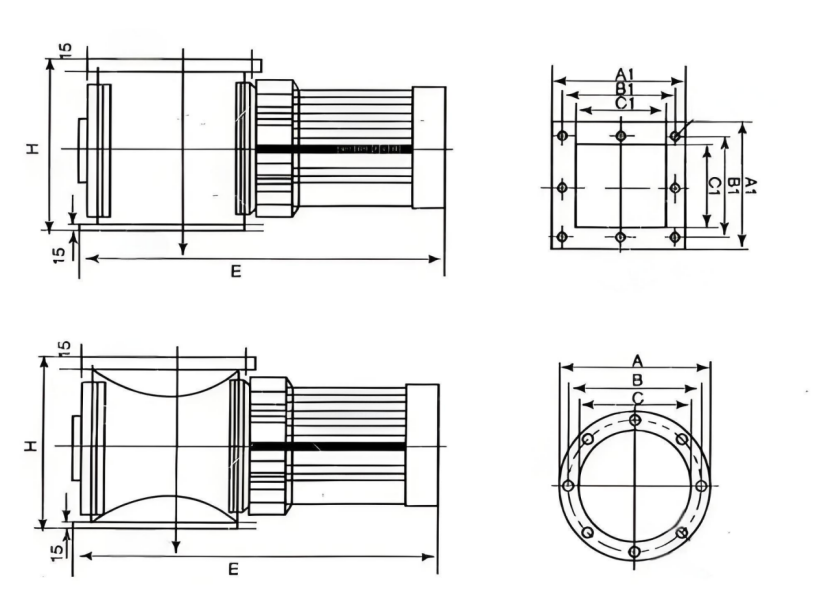

A-shape dimension table(mm):

Type | A | B | C | E | F | M | H | h | n-φ |

YJD02 | 240 | 200 | 150 | 650 | 420 | 122.5 | 225 | 12 | 8-9 |

YJD04 | 260 | 230 | 180 | 758 | 526 | 140 | 280 | 15 | 8-11 |

YJD06 | 280 | 250 | 200 | 778 | 536 | 150 | 300 | 15 | 8-11 |

YJD08 | 300 | 270 | 220 | 798 | 546 | 160 | 320 | 18 | 8-11 |

YJD10 | 320 | 290 | 240 | 880 | 628 | 170 | 340 | 18 | 8-13 |

YJD12 | 340 | 310 | 260 | 900 | 638 | 180 | 360 | 18 | 8-13 |

YJD14 | 360 | 330 | 280 | 920 | 648 | 190 | 380 | 20 | 8-17 |

YJD16 | 380 | 350 | 300 | 960 | 678 | 200 | 400 | 20 | 8-17 |

YJD18 | 400 | 370 | 320 | 980 | 688 | 220 | 440 | 22 | 8-17 |

YJD20 | 420 | 390 | 340 | 1000 | 698 | 230 | 460 | 22 | 8-17 |

YJD26 | 480 | 450 | 400 | 1150 | 740 | 260 | 520 | 24 | 8-17 |

YJD30 | 600 | 520 | 440 | 1190 | 755 | 300 | 600 | 24 | 12-17 |

B-shape mounting dimension table(mm):

Type | φA | φB | φC | E | F | M | H | h | n-φ |

YJD02 | 250 | 210 | 150 | 650 | 420 | 122.5 | 225 | 12 | 8-9 |

YJD04 | 280 | 240 | 180 | 758 | 526 | 140 | 280 | 15 | 8-11 |

YJD06 | 300 | 260 | 200 | 778 | 536 | 150 | 300 | 15 | 8-11 |

YJD08 | 320 | 280 | 220 | 798 | 546 | 160 | 320 | 18 | 8-11 |

YJD10 | 340 | 300 | 240 | 880 | 628 | 170 | 340 | 18 | 8-13 |

YJD12 | 360 | 320 | 260 | 900 | 638 | 180 | 360 | 18 | 8-13 |

YJD14 | 380 | 340 | 280 | 920 | 648 | 190 | 380 | 20 | 8-17 |

YJD16 | 400 | 360 | 300 | 960 | 678 | 200 | 400 | 20 | 8-17 |

YJD18 | 420 | 380 | 320 | 980 | 688 | 220 | 440 | 22 | 8-17 |

YJD20 | 440 | 400 | 340 | 1000 | 698 | 230 | 460 | 22 | 8-17 |

YJD26 | 500 | 460 | 400 | 1150 | 740 | 260 | 520 | 24 | 8-17 |

Key Features

Typical Applications

download brochure

Please download our document to see specific data of the aservice and how we work.

Let’s Start Work Together

No.218, Xisu Road, Huji Street

HaianHigh-tech Zone (formerly Haian Town)

sales@darko-tech.com

9.00AM – 18.00PM